CNC turning

Accurate and efficient solutions for your projects.

Our company offers top CNC turning services that are tailored to the needs and requirements of our customers.

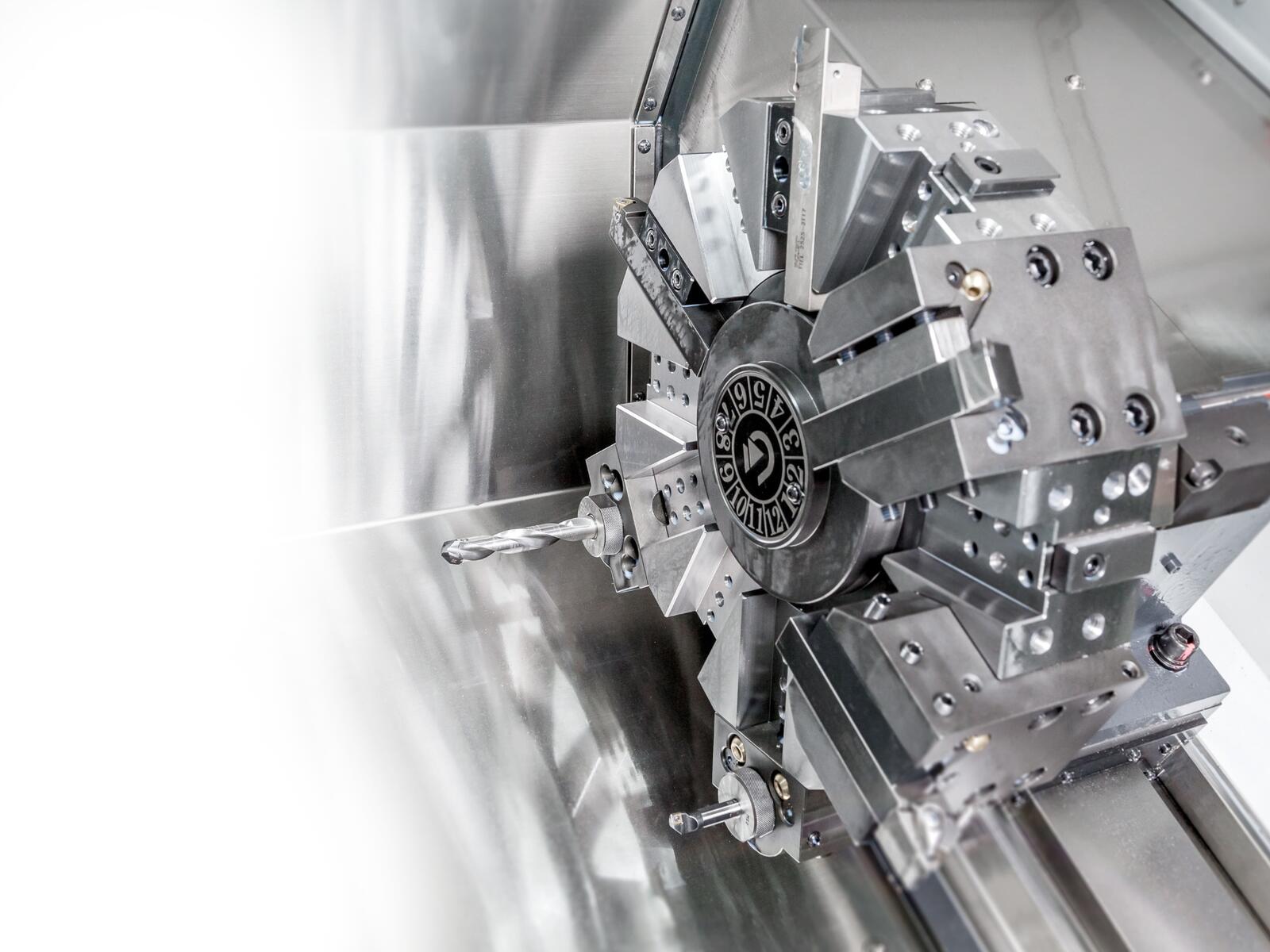

With our modern CNC lathes, we are able to process a wide range of turned parts with maximum accuracy and efficiency.

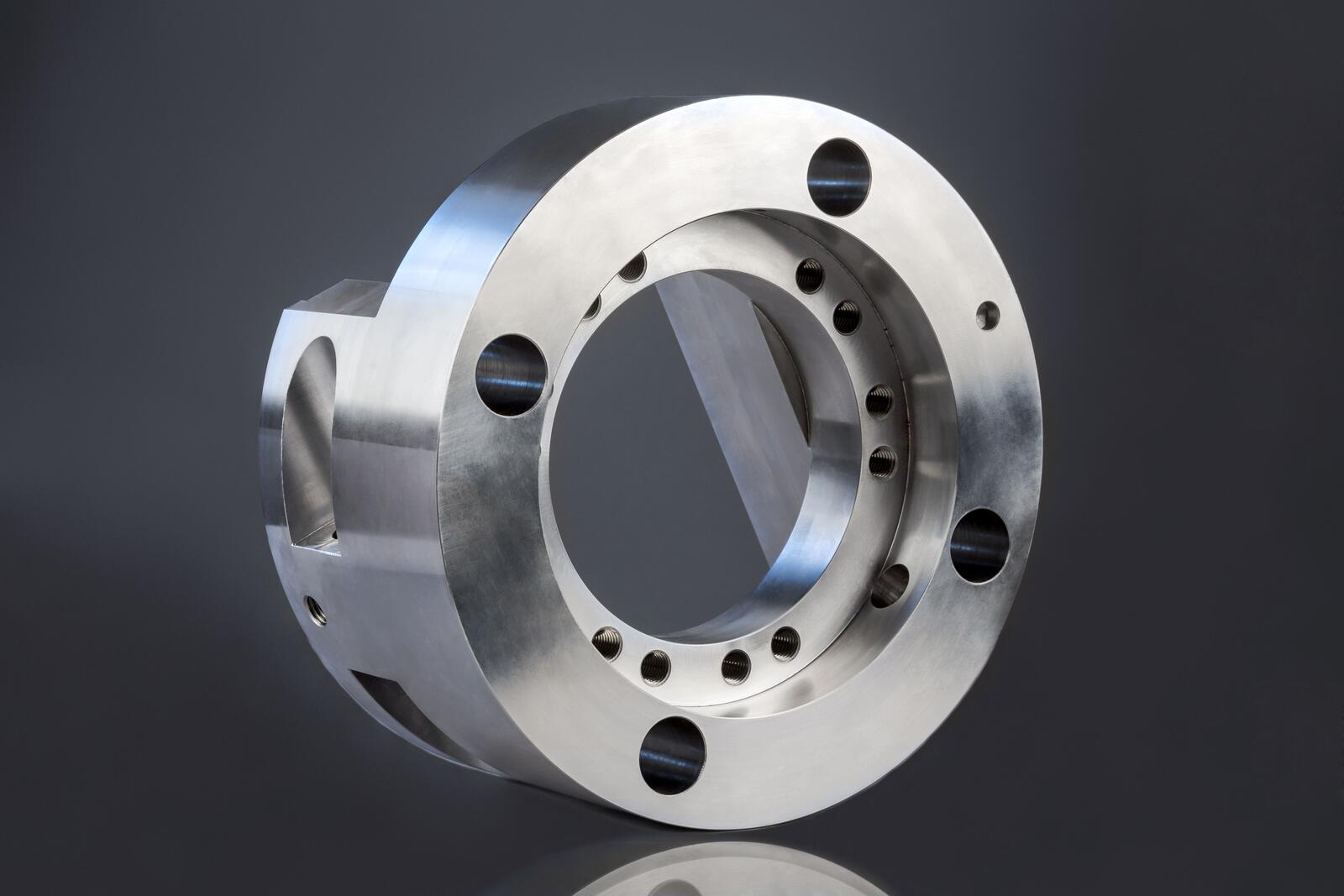

Machining of turned components up to 690 mm

Our large CNC lathes are perfect for machining larger turned parts up to 690 mm in diameter.

These machines are equipped with the latest technologies that enable the fast and accurate production of complex parts such as shafts, cylinders, wheels, or valve bodies.

With these machines, we can effectively respond to the needs of customers who require large dimensions and high accuracy.

Machine equipment for machining of turned components up to 690 mm

SMEC SL 4500A

15" hydraulic chuck

max. turning diameter 690 mm

max. turning length 1,250 mm

spindle bore 117.5 mm

feeds X/Z axis – 350/1,325 mm, slide guide in all axes

Control system: Fanuc 0i-TF

Goodway GA 3300L

12" hydraulic chuck

max. turning diameter 470 mm

max. turning length 1,224 mm

spindle bore 90 mm

feeds X/Z axis – 260/1,230 mm, slide guide in all axes

Control system: Fanuc 0i-TF

Machining of turned components up to 300 mm

For smaller complex parts, we offer machining on our small CNC lathes.

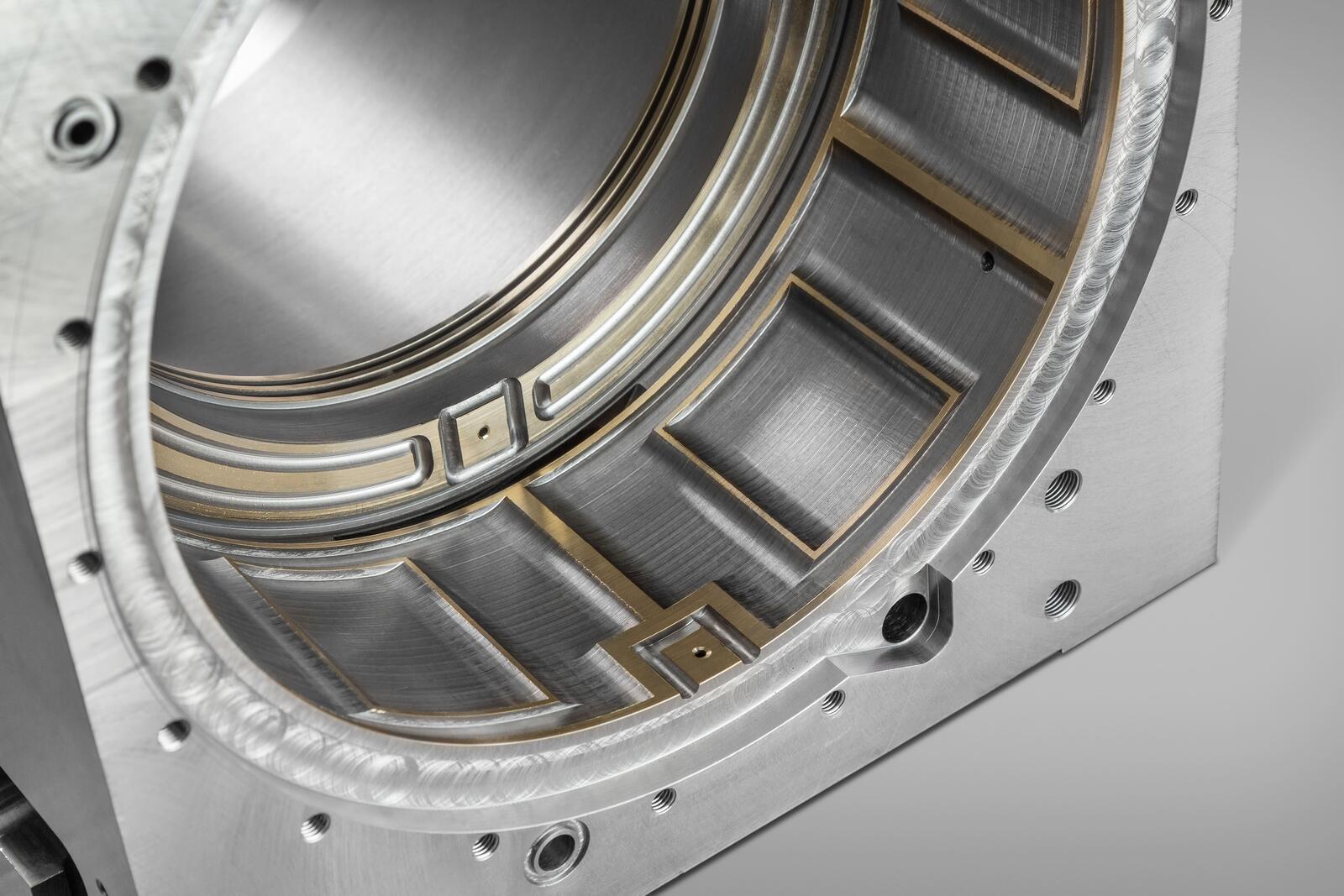

These machines are perfect for machining turned components up to 300 mm in diameter and are equipped for the precise production of flange components, parts such as precision rollers, complex components with internal holes, threads and grooves, and even for components needing additional milling or drilling – provided by driven tools.

Machine equipment for machining of turned components up to 300 mm

Lathe GOODWAY GA-2600

X = 606 mm

Y = 530 mm

Lathe with driven DMG MORI NLX 2500SY-700 tools

X = 260 mm

Y = ±50 mm

Z = 795 mm

B axis = 734 mm

max. machined diameter 366 mm

main 10" spindle 4000 min-1

secondary 6" back spindle 6000 min-1

We use high-quality materials

The choice of material is the foundation for your success, which is why we select the highest quality materials from leading suppliers.

On request, we can provide Inspection certificate 3.1, FDA, REACH-RoHS and certificates for the aerospace industry.

- Structural steel

- Tool steel

- Stainless steel

- Aluminium alloys

- Brass

- Bronze

- Grey cast iron

- Titanium

Cooperation

Each project is unique to us and deserves an individual approach. Thanks to our extensive technological equipment and experience, we are able to offer small batch production of complex parts exactly to your technical drawings and specifications.

Regardless of the complexity or size of your parts, our team of experts ensures that the resulting components meet the highest standards of quality and accuracy.

Frequently asked questions

Are you ISO 9001 certified?

Yes, our company GENICZECH-M, spol. s r. o. is ISO 9001:2016 certified. This certificate ensures that our processes and services meet high quality standards and that we continuously work to improve them, taking into account the needs and expectations of our customers. You can therefore rely your parts being produced to the highest standards, which guarantees the quality and reliability of the products and services delivered.

What part dimensions do you produce?

We specialize in the small-batch production of machined parts. We have a wide range of modern machines that allow us to produce parts in different dimensions and tolerances. See the information on maximum part dimensions for various types of machining below:

- Lathe: We manufacture turned components with diameters ranging from 10 mm to 660 mm, which allows us to flexibly respond to diverse requirements of our customers.

3-axis milling: Our 3-axis milling machines can machine parts up to maximum dimension of 3,000 × 1,500 mm, allowing us to process large pieces of material.

5-axis milling: We also use 5-axis milling, especially for the most complex and precise parts. Using this equipment we are able to machine cylindrical parts with a diameter of up to 800 mm and a height of up to 600 mm.

Flat Grinding: Our surface grinding machines can machine parts up to 1,200 × 520 mm, allowing us to achieve high precision and excellent surface quality.

Circular Grinding: For rounded parts, we offer grinding with a maximum diameter of 250 mm, which is great for finishing turned elements.

We always strive to meet the requirements of our customers and offer optimal solutions for the production of their parts. Should you have any specific requirements or questions about your project, do not hesitate to contact us. We are here to help you find the best solution for your needs.

How long will it take to deliver my order?

Regular parts can be dispatched within 6 weeks from being ordered. If special surface/heat treatments are required, the time is extended by 1–2 weeks.

How much will it cost us?

We will tell you the price after receiving the complete production documentation, ideally with a 3D model of the part. We usually process a quote within 3–5 business days.

What measurement reports do you provide? Can you arrange for complete part metrology with possible certification?

Our company has a comprehensive measurement and quality assurance system that allows you to have full confidence in the accuracy and quality of parts produced for you. For each part that we produce, we are able to provide dimensional reports according to your specifications and requirements. We can draw up these reports based on our own standards or we can use your template.

We also provide various types of attestations, including 2.1, 2.2, 3.1, FAI, and REACH and RoHS compliance statements. If you need to perform special tests such as capillary tests or pressure tests up to 0.8 MPa, we are also ready to provide these services.

Our equipment includes a Wenzel XO 55, a cutting-edge 3D measuring machine which allows us to accurately measure both conventional and more complex spherical shapes, and to compare 3D contours with a digital model of the part. In addition, we also have other precision measuring tools such as roughness meters, altimeters, and micrometers, primarily from renowned manufacturers like Mitutoyo.

Our company is certified according to ISO 9001:2016, which ensures that all our processes and measuring reports comply with the highest quality standards.

If you have further questions about our measurement reports or need additional information, please do not hesitate to contact us. We are here to help and ensure that you are fully satisfied with the results of our work.

Can you provide me with surface or heat treatment?

Yes, at GENICZECH-M spol. s r.o. we are able to provide surface treatment and heat treatment for parts that we have produced ourselves. Surface and heat treatments are an important step in the manufacturing process, which increases the durability of the product and its aesthetic quality. So you can count on us to provide you with a complete service when we manufacture parts for you. More information about surface and heat treatments can be found here.

If you have specific requirements or need further information about the options and types of finishes we offer, please do not hesitate to contact us. We are here to provide you with a complete and high-quality service tailored to your needs.

Will you assemble my line if I deliver my own parts?

No, we at GENICZECH-M, spol. s r.o. perform assembly work exclusively for units and machines that have been manufactured by us. Because we have complete control over the entire production process from start to finish, this approach allows us to ensure the highest possible quality and reliability of the final assembled units. If you are interested in comprehensive services, including the production of parts and their subsequent assembly, we will be happy to discuss your requirements and offer you a solution tailored to your needs. Contact us for further information and cooperation opportunities.