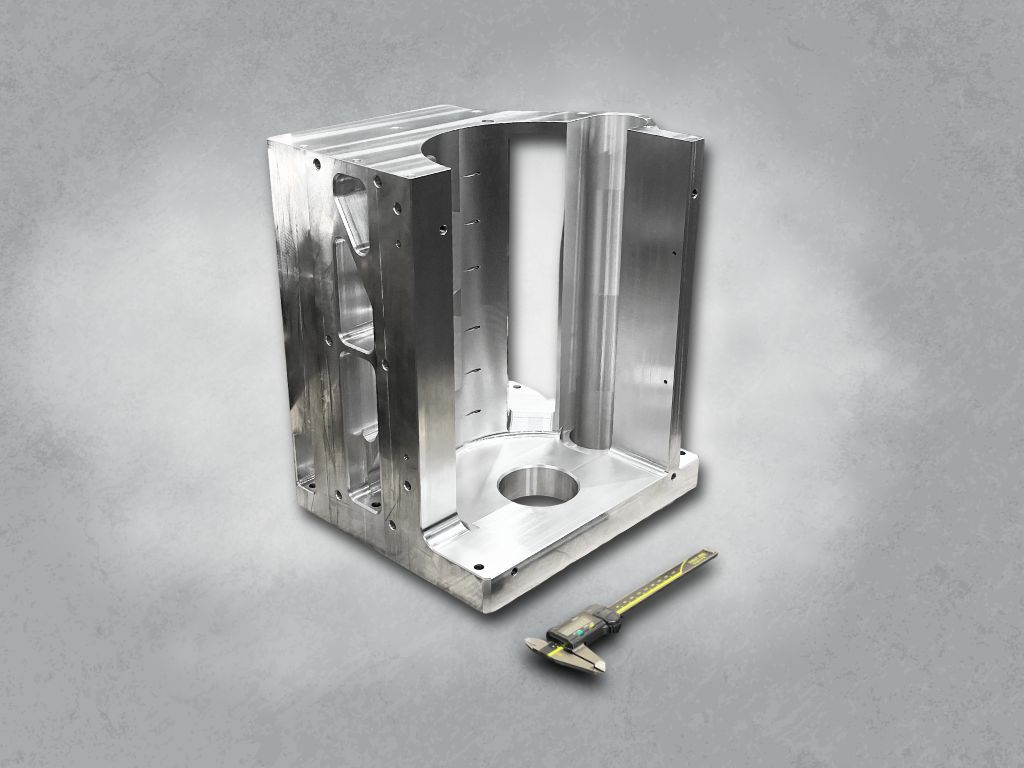

During the production of this complex part, maximum emphasis was placed on very precise dimensional and geometric tolerances.

Production procedure:

We start with a 150 mm diameter rolled bar made from 11523 structural steel, which goes onto our Goodway GA3300 CNC lathe where the part takes its basic shape. Next comes our DMU 60 5-axis machining centre, which does all the milling, drilling and prepares the saddles for final grinding.

And the grinding is where the real magic lies! Outer diameters are ground to 95 mm within a tolerance of m6 and inner diameters to 68+0.01 mm. The part is very demanding not only for its dimensional tolerances but also for its geometric tolerances. In fact, the elements between them must meet a geometric tolerance of circumferential runout of only 0.02 mm! That's a precision thinner than a human hair!

We are GENICZECH-M, a Zlín-based engineering company.

We produce precision machined parts according to customer documentation. We assemble structural units and machines. We provide surface and heat treatment and transport anywhere in the world.

Our custom production is mainly directed to packaging machines for the pharmaceutical or food industry, also to machine tools, printing or paper machines. Production for the aerospace or electrical industry is no exception.

More information about our technology can be found HERE.